| Issue |

EPJ Photovolt.

Volume 15, 2024

Special Issue on ‘EU PVSEC 2023: State of the Art and Developments in Photovoltaics’, edited by Robert Kenny and João Serra

|

|

|---|---|---|

| Article Number | 5 | |

| Number of page(s) | 8 | |

| DOI | https://doi.org/10.1051/epjpv/2024006 | |

| Published online | 15 February 2024 | |

https://doi.org/10.1051/epjpv/2024006

Mini-review

Update of quality control tests for new PV encapsulation materials

1

PI Photovoltaik-Institut Berlin AG (PI Berlin), Wrangelstr. 100, Berlin 10997, Germany

2

Fraunhofer-Center für Silizium-Photovoltaik CSP, Otto-Eißfeldt-Straße 12, 06120 Halle, Germany

* e-mail: lust@pi-berlin.com

Received:

29

September

2023

Accepted:

15

January

2024

Published online: 15 February 2024

Although ethylene vinyl acetate copolymer (EVA) is still the dominant PV encapsulant, polyolefins (PO) have gained market share in recent years. Like EVA, PO can be mixed with a cross-linking agent and chemically reacted during the lamination process to form polyolefin elastomers (POE). The cross-linked and therefore insoluble fraction of the encapsulation can be determined by extracting the soluble part of the material with a solvent. The degree of cross-linking, or gel content (GC), is determined from the mass ratio before and after extraction of the samples. The analytical methods for determining the GC value are described for example in IEC 62788-1-6 and the Chinese national standard GB/T29848-2018. We observe a significant difference between the test results of these two standards, with the GC values resulting from the GB standard test being significantly higher. This is particularly true in the low GC range. The main reason for this difference is the extraction time of 5 h specified in the GB standard, which is insufficient to ensure complete extraction of the non-crosslinked polymers at lower GC values. However, for certain POE materials the required minimum GC (50%-65%) is exactly in this range.

Key words: PV modules / Encapsulant / POE / Gel content / Reliability testing

© S. Lust et al., Published by EDP Sciences, 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Although ethylene vinyl acetate copolymer (EVA) is still the dominant PV encapsulation material, polyolefins (PO) have gained market share in recent years [1]. Polyolefins consist of an alkane backbone with various side groups, with the vinyl acetate side groups of EVA being replaced by acrylates, acrylic acids or n-alkanes to prevent the formation of acetic acid. Like EVA, PO can be mixed with a cross-linking agent and chemically react during the lamination process to form polyolefin elastomers (POE). Furthermore, EVA-POE (EP) and EVA-POE-EVA (EPE) multilayer films are increasingly coming onto the market [1]. All the materials mentioned can be used on the front and/or the rear of the module. POE films do not contain corrosive acetic acid as a degradation product; they are less permeable to vapour and have a lower conductivity than EVA, thus reducing PID.

The cross-linking reaction initiated by the thermal process in the laminator is essential for the material properties of the encapsulation films and thus for the long-term stability of the module [2–8]. The cross-linked and thereby insoluble fraction of the encapsulation can be determined by extracting the soluble part of the material with solvent. The degree of cross-linking or gel content (GC) results from the ratio of sample masses before and after extraction procedure. Manufacturer recommended GC values for commercially available POE, EVA and EPE encapsulation materials are shown in Table 1 [1]. The recommended lower limits of GC for POE are between 50% for CONSERV E 360 (Renewsys.) and 70% for PO8110 (Sinopont) and SE-556 (SVECK). For the two EPE films the recommended lower limit is 70%, for EP 80% and for the EVA films 75% and 80%.

The analytical methods for determining the GC value are described in ASTM D2765, IEC 62788-1-6 and the national Chinese GB/T29848-2018 standard, hereafter referred to as ASTM, IEC and GB standard. In mass production, regular lamination tests with subsequent analysis of the GC provide the module manufacturer with information on the quality of the front and back encapsulant used. For determination of the GC of processed modules, the encapsulant material has to be mechanically extracted from the module. In practice, the GC of only one of the two encapsulation films is measured, usually the encapsulant at the back of the solar module. As shown previously, the GC values of the two encapsulants in the module may differ depending on the type of material, so both sides must be tested [9].

While European research institutes mainly adhere to the IEC standard, Chinese solar module and encapsulant manufacturers follow the GB standard.

Module quality assurance is a core business of PI Berlin and includes factory audits as well as post-production inspection. Tests of accelerated aging would be ideal to assure longterm reliability of modules, but take long time and are expensive. A considerable and fast growing market share consists of glass-glass modules [1], for which peel tests for adhesion are no longer possible. As PI Berlin deals with a huge variety of already processed modules, calibration is not possible, so indirect measurements like dynamic mechanical analysis (DMA) are of limited use. Chemical determination of the GC value is therefore the only measurement which gives a hint about the quality of the encapsulant and thereby of the long-term stability of the module.

Most solar modules are currently manufactured in China, which means that the Chinese national standard is used for in-house production control, factory audits and pre-shipment testing. Post-shipment testing for PI Berlin's European customers, on the other hand, is carried out in the Berlin laboratory according to the IEC standard. We observe a significant difference between the test results of the two standards, with the GC values resulting from the GB standard test being significantly higher than those measured at PI Berlin. For confidentiality reasons, the results of tests on customer solar modules cannot be published. Instead, a round robin test has therefore been carried out to illustrate the phenomena, the results of which are presented in Section 3.1. We apply the GB and the IEC standard to encapsulation material with a low GC value and investigate what effects might explain the different results of the two standards and how they could be modified to provide meaningful results for the low GC range and thus for application to POE material.

2 Material and methods

2.1 Sample preparation

POE (TF4, First, see Tab. 1) 5 cm × 10 cm samples were produced using a laminator S1815 from S3 Swiss Solar System AG. Preliminary measurements using an external thermal sensor ensured that the temperature inhomogeneities within the area of the laminated samples were below +/−2 °C. The evacuation time was 5 min, the curing time was 15 min and the temperature was changed from 120 °C to 170 °C in 10-degree Celsius steps. After the lamination the samples were cut into approximately (5 × 5) mm2 pieces. To ensure comparability, the resulting particle pile was then thoroughly mixed for each parameter set and divided into four samples with identical properties. For in-house testing to the GB standard, two of the samples were then further reduced to a particle size of approximately (1 × 1) mm2 (PI Berlin) and (2.5 × 2.5) mm2 (Laboratory A).

2.2 Gel content tests

The aim of the round robin was to compare existing commercially available standard GC test procedures for solar module testing. Only the standard GC test setup at PI Berlin was specifically designed for this test series and was therefore expected to be identical to the setup at Lab A. The extraction conditions are summarized in Table 2.

The inhouse cross-linking tests according to IEC standard were carried out using tetrahydrofuran (THF) as solvent and a Soxhlet-like fluidised bed hot extraction (fexIKA®) apparatus. The sample is fixed in a stainless-steel wire mesh container in a glass tube above the boiling solvent. During the heating period the THF evaporates and recondenses at the reflux condenser so that the sample in the glass tube is flushed with freshly distilled solvent. At the end of the heating period, cooling leads to a pressure drop, which causes the used solvent containing dissolved polymers flowing back into the reaction flask. One cycle of heating and cooling lasts approximately 6 min, the substrate was immersed in solvent for approximately 2 min each. 150 cycles have been performed unless otherwise stated. For each laminate and parameter set three extractions were performed and the mean GC value was calculated.

For inhouse cross-linking tests according to GB standard, samples were placed in a 120 mesh stainless steel bag which was sealed with a wire and placed in a 500 ml round bottom flask with three ports. More than half the volume of the flask was filled with xylene solvent so that the sample packet was immersed in the solvent. A reflux condenser was positioned in the center of the flask. The solvent was heated to approximately 140 °C, which is the boiling point of xylene. The extraction time was 5 h unless otherwise stated. The reflux rate was maintained at 20 to 40 drops/min. After refluxing, the sample packet was immediately removed from the solvent unless otherwise noted. Two tests per data point were performed and the mean GC value and the standard deviation were calculated.

For the round robin test described in Section 3.1, GC values were additionally measured at a commercial Chinese lab according to the GB standard and at Fraunhofer CSP Halle according to the IEC standard, the latter using toluene as solvent. For these tests as well, two tests were carried out for each data point.

The measurement error is given as the standard deviation, bearing in mind that the true standard deviation is underestimated due to the small number of measurements (n = 2 or n = 3). (A sample size of n = 2 is common practice in the solar industry and meets the requirements of the standards analysed for the GC test).

Extraction parameters of the participating laboratories using IEC FDIS 62788 (IEC) and GB/T29848-2018 (GB) standard.

3 Results

3.1 Round robin

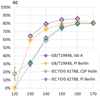

To test the applicability of the GC tests to low GC values and therefore to POE materials, a lamination series was prepared in which the temperature was varied from 120 to 170 °C in 10 °C increments. The resulting samples were tested at PI Berlin and sent to two external laboratories to measure the gel content. A Chinese laboratory used the method as described in the GB standard and a German laboratory - the Fraunhofer CSP in Halle – as described in the IEC standard (using toluene as a solvent). At PI Berlin, both methods were tested, the results are shown in Figure 1.

The degree of cross-linking shows a dependence on the lamination temperature, which is typical for chemically cross-linked films. Cross-linking reaction starts above a certain temperature threshold of around 120 °C with the degree of cross-linking increasing sharply at lower temperatures then reaching a plateau where no further cross-linkage could be detected. The extractions following the GB standard show consistently higher values than the tests based on IEC standard. In addition, the tests according to the GB standard also showed discrepancies between the two laboratories. Whilst similar values are obtained in the plateau region with the different methods, there are large differences in the lower temperature regions. For example, the sample laminated at 130 °C show GC values above and around 60% (lab A: 64,4%, PI Berlin: 59,5%) with GB based GC tests, whereas the GC values for tests based on IEC standard were substantially lower (Fraunhofer CSP: 31,8%, PI Berlin: 30,4%). Deviating values were obtained for POE 120 sample: 18% GC was measured at CSP Halle, while in the two tests at PI Berlin the samples were completely dissolved and no cross-linking could be detected. Since the encapsulant suppliers recommend GC values of 60% and above, these differences cannot be neglected and are therefore further analysed in the following sections.

|

Fig. 1 GC values of POE (TF4) samples laminated for 15 min at various temperatures and tested per GB/T29848 and IEC 62788-1-6 standard. |

3.2 Comparison of the international standards

Table 3 shows the main similarities and differences between the ASTM, the IEC and the GB standard.

The ASTM and GB standards use a round bottom flask with a reflux condenser; the sample is immersed directly in the boiling solvent. In this case the extraction temperature is equal to the boiling point of the solvent. The IEC standard requires the use of a Soxhlet or similar apparatus. The sample is placed above the boiling solvent and the extraction is carried out in cycles with freshly distilled liquid. The extraction temperature is close to or below the boiling point of the solvent. The ASTM specifies xylene or decahydronaphthalene as the solvent. Only xylene is accepted in the GB standard. Xylene has a boiling point of 138 – 140 °C. The IEC standard uses xylene as standard, toluene (boiling point 111 °C) and tetrahydrofuran (THF, boiling point 64 °C) are acceptable, but the extraction time must be adjusted for these alternative solvents.

The ASTM and IEC standards require the addition of an antioxidant, which is 2% by weight of the encapsulant in the IEC standard and 1% by weight in the ASTM standard. Various antioxidants can be used, such as 2,2′-methylenebis(4-methyl-6-tert-butylphenol) or 2,6-di-tert-butyl-4-methylphenol (BHT). The IEC justifies this by the need to prevent cross-linking during extraction, and the ASTM by the need to prevent oxidation of the polymer.

The required extraction times are 12 h for the ASTM standard and only 5 h for the GB standard. The IEC standard requires an extraction time of 8 to 12 h and 15 or more cycles per hour and specifies that the extraction time must be adjusted for low GC values.

In the GB standard the sample is heated with the solvent, in the ASTM standard it is added to the already heated solution. Neither standard specifies when the sample is taken after extraction. For the IEC standard these specifications are not necessary as the sample is extracted with freshly distilled solvent, which is only produced when the solvent has reached its boiling point.

Main similarities and differences between the three standards ASTM 2765-16, IEC FDIS 62788 and GB/T29848-2018.

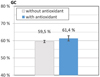

3.3 Role of antioxidant (stabiliser)

According to the IEC standard, the function of the antioxidant added to the solvent is to prevent further cross-linking during extraction (stabliser). As shown in Section 3.1, cross-linking is to be expected at temperatures above 120 °C, whereas the boiling points of THF and toluene are 64 °C and 111 °C respectively.

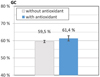

The GB standard does not mention the use of an antioxidant, while xylene has a boiling point of 140 °C and in the GB standard, the sample is placed directly in the boiling solvent. It is therefore possible that post-crosslinking takes place during extraction, resulting in an increased GC value. To test this hypothesis, GC tests of the 130 °C sample were performed with and without the addition of 0.1 g of the antioxidant 2,6 di-tert-butyl-4-methylphenol (BHT). This amount represented 10% by weight of the POE sample, ten times the amount required by the ASTM standard. The extraction took place for 5 h at around 140 °C. Particle sizes of the POE samples were approximately (1 × 1) mm2.

Figure 2 shows the GC values for the treatment in xylene with and without antioxidant. The values were found to be equal within the limits of standard deviation, with a slightly increased GC value in the case of extraction with addition of BHT.

If post-crosslinking were to occur during extraction, the GC value for the GC test without stabiliser should be higher than for the test with stabiliser. Thus, post-crosslinking does not seem to take place even without the addition of the stabiliser.

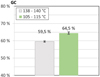

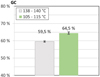

Below 120 °C no cross-linking takes place for the POE material used (see Sect. 3.1). In the following test, the temperature during extraction in xylene was limited to 105-115 °C and thus below the temperature at the start of cross-linking. The extraction took place for 5 h, no antioxidant was added, particle sizes of the POE samples were approximately (1 × 1) mm2. The test results are shown in Figure 3.

The GC value after 5 h of extraction at 105 – 115 °C is clearly above the value for 140 °C, most likely, the extraction being less efficient at lower temperatures. This also indicates that no post-cross-linking took place during the extraction.

For the inter-laboratory test presented in Section 3.1, it can therefore be excluded that the difference in low GC values for the GB standard is due to post-crosslinking during extraction in xylene. However, these results must be treated with caution as the GC tests were carried out weeks after lamination. Although the samples were stored airtight and in the dark, decomposition or evaporation of the cross-linking agents cannot be excluded. It is possible that post-crosslinking may occur if the test is performed immediately after lamination. It may therefore be appropriate to use BHT prophylactically until further tests provide a complete picture.

|

Fig. 2 GC values of POE (TF4) samples laminated at 130 °C for extraction with (left) and without (right) antioxidant (BHT). |

|

Fig. 3 GC values of the 130 °C POE samples obtained with GB/T29848-2018 standard tests after 5 h for extraction at 138 – 140 °C (left) and 105 – 115 °C (right). |

3.4 Extraction duration

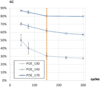

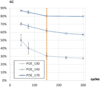

To evaluate the possible influence of treatment length on the measured GC value, samples laminated at 130, 140 and 170 °C were subjected to extraction tests of different durations. Particle sizes of the POE samples were approximately (1 × 1) mm2.

Figure 4 shows the results for GB standard tests with extraction times of 5, 10, 20 and 100 h. The extraction temperature was around 140 °C, no antioxidant was added. Figure 5 shows the results for IEC standard tests with 45, 75, 150 and 300 cycles, also corresponding to an increase in treatment time. In both cases the gel content value decreases as the extraction time increases. The lower the degree of cross-linking, the greater this effect. The dotted lines represent the extraction times used in the interlaboratory comparison: 5 h as described in the GB standard and 150 cycles for the IEC standard.

Obviously, the non-crosslinked part of the POE film is not completely dissolved after extraction, the extraction time is too short. The gel content values measured here do not represent a “real” degree of cross-linking, but a value artificially increased by an undefined amount of non-cross-linked but still undissolved material. This especially applies to the GB standard. The lower the degree of cross-linking, the stronger the effect. This is easily explained by the fact that the amount of uncured material to be extracted is greater at low GC values. For example, at a GC value of 60%, twice as much material must be dissolved as at a GC value of 80%.

It can be concluded that for both of the tests performed, the extraction length needs to be increased when analysing POE. The IEC standard is applicable to POE as it already specifies that the treatment time must be extended at low GC levels. However, standard laboratory test procedures must be adapted accordingly. In contrast, the rigid extraction time of 5 h specified in the GB standard is not sufficient to ensure complete extraction of non-crosslinked polymers, especially at lower GC values.

|

Fig. 4 GC value of the 130, 140 and 170 °C POE samples as a function of the extraction duration for the GB/T29848-2018 standard. |

|

Fig. 5 GC value of the 130, 140 and 170 °C POE samples as a function of the number of cycles performed according to the IEC FDIS 62788 standard. |

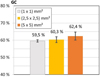

3.5 Influence of particle size

To ensure comparability, the laminates were cut into approximately (5 × 5) mm2 pieces, which were then thoroughly mixed to produce samples with identical properties (see Sect. 2.1). In order to test the influence of particle size on the measured GC value, samples with roughly (5 × 5) mm2 particle size were further cut down to particle sizes of approximately (2.5 × 2.5) mm2 and (1 × 1) mm2. Figure 6 shows the GC value as a function of particle size.

A slight decline in GC values with decreasing particle size can be observed. This effect can be explained by the specific surface, which becomes larger for smaller particles making the particles more exposed to the surrounding surface thus facilitating the extraction. While this difference of the three sizes stays within the range of the error bars, it is an additional hint that extraction is not completed when applying the GB standard.

The ASTM standard requires ground particles that pass through 30 mesh, but not 60 mesh. In this case, the sample sizes are well below 1 mm2. Compared to the GB standard, not only is the extraction time longer (12 h instead of 5), but also the particles size is prescribed to be significantly smaller. Under these conditions it can be assumed that the ASTM standard extraction is sufficient even for low GC values. Further tests in this regard are currently being carried out.

|

Fig. 6 GC values of the 130 °C POE samples obtained with GB/T29848-2018 standard tests, varying the particle size. |

3.6 Influence of the measurement mode

Since the encapsulant manufacturers are also almost exclusively based in China and also perform their GC measurements according to the GB standard, it could be argued that it is unnecessary to determine a “real” GC value if the measured value is precisely defined by the GB standard and therefore reproducible. However, the influence of particle size (see Sect. 3.5) has already indicated that incomplete extraction of the non-crosslinked polymers can lead to a lack of reproducibility. The influence of sample placement and sampling on the measured GC value is determined and shown below.

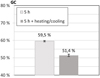

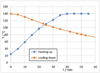

Figure 7 shows the GC value of a 130 °C sample (particle sizes 1 × 1 mm2) treated for 5 h. In the second extraction, the sample was placed in the cold solution, heated with the solvent, extracted for 5 h. The sample was then left in the cooling solvent overnight and was not removed until the following morning, after approximately 15 h.

This example shows that a GC value distorted by non-crosslinked material is difficult to reproduce.

|

Fig. 7 GC value of the 130 °C POE samples obtained with GB/T29848-2018 standard tests after 5 h (left) and after 5 h with additional heating up and cooling down periods (right). Heating and cooling ramps are shown in Figure 8. The first case - an exact extraction time of 5 h - is likely where a laboratory has a lot of samples to process and wants to run the test continuously without cooling and heating the solvent between tests. The second case may occur when the laboratory is less busy or safety requirements prohibit sampling from the 140 °C hot reaction flask. The difference is about 8%, one sample almost reaching the 60% gel content recommended by the manufacturer. |

|

Fig. 8 Heating and cooling ramp for the GB/T29848-2018 tests conducted at the PI Berlin. |

4 Conclusions

The aim of this work was to extend the existing GC tests for POE. POE, like EVA encapsulants, contains peroxides which chemically cross-link the PO polymers to form a three-dimensional network. Therefore, it is possible to determine the GC value of POE encapsulants by chemical extraction. Yet GC tests for solar modules have been developed for and with the use of EVA. The lower limits for GCs recommended by manufacturers vary for POE and are often significantly lower than the values for EVA. Since cross-linking degrees of 75% and higher are required for EVA films (see chapter I), the area of low GC values has not been the focus of scientific investigations so far. However, for certain POE materials, the required minimum GC is exactly in this range.

The applicability of the GC tests to low GC values and therefore to POE materials, were tested with a lamination series in which the temperature was varied from 120 to 170 °C. Whilst similar values are obtained in the plateau region with the different methods, there are large differences in the lower temperature regions.

Using the standard procedure, the non-crosslinked part of the POE film does not completely dissolve after extraction, as could be shown by varying the extraction time. The gel content values measured here do not represent a “real” degree of cross-linking, but a value artificially increased by an undefined amount of non-cross-linked but still undissolved material. This especially applies to the GB standard. The lower the degree of cross-linking, the stronger the effect.

The aim of this work was to further develop existing GC tests for POE. The focus was on the analysis of four methods currently in commercial use in the solar industry. The extraction methods used varied, as did the solvent used and, consequently, the extraction temperature and the solubility of the non-crosslinked polymers. Further analysis is required to differentiate the influence of each parameter.

For the inter-laboratory test results presented in this study, it can be excluded that the difference in low GC values for the GB standard is due to post-crosslinking during extraction in xylene. This result must be treated with caution as the GC tests were carried out weeks after lamination, so that the crosslinking agents had possibly already decomposed or evaporated. It can therefore not be ruled out that post-crosslinking occurs if the sample is subjected to a GC test determination according to the GB standard directly after lamination.

It can be concluded that for IEC standard as well as for the GB standard tests, the extraction length needs to be increased when analysing POE. The IEC standard already provides for a variable extraction time depending on the GC values. However, the extraction time of 5 h specified in the GB standard is not sufficient to ensure complete extraction of the non-crosslinked polymers at lower GC values. The authors suggest increasing the extraction time of the GB standard to at least 20 h.

Conflicts of interest

The authors have nothing to disclose.

Funding

This work was supported by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) under the contract number 03EE1112D, acronym EVA plus.

Data availability statement

This article has no associated data generated.

Author contribution statement

Equal contribution of all authors except for original draft preparation, writing – review & editing, S.L.

References

- S.K. Chunduri, M. Schmela, TaiyangNews Market Survey Backsheets & Encapsulation 2022–2023. TAIYANGNEWS. Düsseldorf 2023. https://taiyangnews.info/solar-backsheets-encapsulants-market-survey-2022-23/ (retrieved 30.11.2023) [Google Scholar]

- M. Aghaei, A. Fairbrother, A. Gok, S. Ahmad, S. Kazim, K. Lobato, G. Oreski, A. Reinders, J. Schmitz, M. Theelen, P. Yilmaz, J. Kettle, Review of degradation and failure phenomena in photovoltaic modules, Renew. Sust. Energy Rev. 159, 112160 (2022) [CrossRef] [Google Scholar]

- A.K. Öz, C. Herzog, C. Wellens, D.E. Mansour, M. Heinrich, A. Kraft, The impact of the lamination process on the adhesion properties at the glass-encapsulant interface and damp heat stability of PV modules, in 38th EUPVSEC (2021), https://doi.org/10.4229/EUPVSEC20212021-4AV.1.5 [Google Scholar]

- G. Oreski, A. Omazic, G.C. Eder, Y. Voronko, L. Neumaier, W. Mühleisen, C. Hirschl, G. Ujvari, R. Ebner, M. Edler, Properties and degradation behaviour of polyolefin encapsulants for photovoltaic modules, Prog. Photovolt. Res. Appl. 28, 1277 (2020) [CrossRef] [Google Scholar]

- S. Pingel, S. Janke, B. Stannowski, S. Fechner, L. Podlowski, Advanced testing of PV module encapsulants, in 35th EUPVSEC (2018), https://doi.org/10.4229/35thEUPVSEC20182018-5CV.3.38 [Google Scholar]

- G. Oreski, A. Rauschenbach, C. Hirschl, M. Kraft, G.C. Eder, G. Pinter, Crosslinking and post-crosslinking of ethylene vinyl acetate in photovoltaic modules, J. Appl. Polym. Sci. 134, 44912 (2017) [CrossRef] [PubMed] [Google Scholar]

- C. Hirschl, M. Biebl-Rydlo, M. DeBiasio, W. Mühleisen, L. Neumaier, W. Scherf, G. Oreski, G. Eder, B. Chernev, W. Schwab, M. Kraft, Determining the degree of crosslinking of ethylene vinyl acetate photovoltaic module encapsulants – a comparative study, Sol. Energy Mater. Sol. Cells 116, 203(2013). [CrossRef] [Google Scholar]

- A.W. Czanderna, F.J. Pern, Encapsulation of PV modules using ethylene vinyl acetate copolymer as a pottant: a critical review, Sol. Energy Mater. Sol. Cells 43, 101 (1996) [CrossRef] [Google Scholar]

- S. Lust, N. Schnitzler, A. Brendler, S. Wendlandt, T. Weber, S.R. Kuntamukkula, A. Mordvinkin, M. Wendt, Challenges for Quality Control Posed by New PV Encapsulation Materials, in 40th EUPVSEC (2023), https://doi.org/10.4229/EUPVSEC2023/3DO.19.3 [Google Scholar]

Cite this article as: Sandra Lust, Thomas Weber, Shiva Ram Kuntamukkula, Anton Mordvinkin, Michael Wendt, Update of quality control tests for new PV encapsulation materials, EPJ Photovoltaics 15, 5 (2024)

All Tables

Extraction parameters of the participating laboratories using IEC FDIS 62788 (IEC) and GB/T29848-2018 (GB) standard.

Main similarities and differences between the three standards ASTM 2765-16, IEC FDIS 62788 and GB/T29848-2018.

All Figures

|

Fig. 1 GC values of POE (TF4) samples laminated for 15 min at various temperatures and tested per GB/T29848 and IEC 62788-1-6 standard. |

| In the text | |

|

Fig. 2 GC values of POE (TF4) samples laminated at 130 °C for extraction with (left) and without (right) antioxidant (BHT). |

| In the text | |

|

Fig. 3 GC values of the 130 °C POE samples obtained with GB/T29848-2018 standard tests after 5 h for extraction at 138 – 140 °C (left) and 105 – 115 °C (right). |

| In the text | |

|

Fig. 4 GC value of the 130, 140 and 170 °C POE samples as a function of the extraction duration for the GB/T29848-2018 standard. |

| In the text | |

|

Fig. 5 GC value of the 130, 140 and 170 °C POE samples as a function of the number of cycles performed according to the IEC FDIS 62788 standard. |

| In the text | |

|

Fig. 6 GC values of the 130 °C POE samples obtained with GB/T29848-2018 standard tests, varying the particle size. |

| In the text | |

|

Fig. 7 GC value of the 130 °C POE samples obtained with GB/T29848-2018 standard tests after 5 h (left) and after 5 h with additional heating up and cooling down periods (right). Heating and cooling ramps are shown in Figure 8. The first case - an exact extraction time of 5 h - is likely where a laboratory has a lot of samples to process and wants to run the test continuously without cooling and heating the solvent between tests. The second case may occur when the laboratory is less busy or safety requirements prohibit sampling from the 140 °C hot reaction flask. The difference is about 8%, one sample almost reaching the 60% gel content recommended by the manufacturer. |

| In the text | |

|

Fig. 8 Heating and cooling ramp for the GB/T29848-2018 tests conducted at the PI Berlin. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.