| Issue |

EPJ Photovolt.

Volume 14, 2023

Special Issue on ‘EU PVSEC 2023: State of the Art and Developments in Photovoltaics’, edited by Robert Kenny and João Serra

|

|

|---|---|---|

| Article Number | 39 | |

| Number of page(s) | 10 | |

| Section | Modules and Systems | |

| DOI | https://doi.org/10.1051/epjpv/2023030 | |

| Published online | 19 December 2023 | |

https://doi.org/10.1051/epjpv/2023030

Regular Article

Mission profile concept for PV modules: use case – middle east deserts vs temperate European climate

1

Fraunhofer Center for Silicon Photovoltaics CSP, Otto-Eissfeldt-Str. 12, 06120 Halle (Saale), Germany

2

DEWA Research & Development Center, P.O. Box: 564 Dubai, United Arab Emirates

* e-mail: bengt.jaeckel@csp.fraunhofer.de

Received:

18

July

2023

Received in final form:

13

September

2023

Accepted:

23

October

2023

Published online: 19 December 2023

The paper addresses the need to simplify the comparison between different climatic conditions. Therefore, the concept of Mission Profiles is introduced to PV. Mission Profiles are a set of climatic stresses compiled to allow direct comparisons such as temperature, humidity, and UV exposure. The use-case in this paper is a comparison of a temperate with a hot climate. The results show that temperature driven processes are highly accelerated for the hot climate, whereas processes that involve humidity may lead to a similar annual degradation. The impact of light, particularly UV, is even more complex. UV triggered reaction processes can be photon absorption triggered and accelerated by temperature. However, for most observed interactions and material changes UV light goes in conjunction with moisture (H2O) for the chemical reaction and is accelerated by temperature. Calculating the impact of temperature and UV is possible. However, the impact of moisture is almost impossible as it requires the knowledge of the local microclimate. Only a “worst-case” scenario can be assumed while using ambient relative humidity for most events of the day, that, however, do typically not include condensation. With the introduction of Mission Profiles, it should be possible to assess stress more easily for particular sites in general. Differences in mounting such as open rack compared to e.g., BiPV can also better addressed, however, with some assumption to define the microclimate (e.g., exclude rear side cooling).

Key words: Mission profile / climate data / degradation / forecast / simulation

© B. Jaeckel et al., Published by EDP Sciences, 2023

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Within the last years the installed number of PV systems dramatically increased and will further grow in the future. In addition to that, the number of different cell architectures (TOPCon, HJT, IBC), electrical interconnection methods (lead free solder, ECA) combined with larger wafer sizes, multiple cut cells and new encapsulation systems [1] require a more in-depth understanding of the environmental loads the PV module experiences in the expected service life.

To keep up with the need to have reasonable prices as well as durable and reliable PV modules for extended service life of more than 20 years, the “one-size-fits all” approach is not appropriate, as the differences in environmental stress conditions are very diverse. They not only vary from location to location, but also vary from type of installation such as open-rack vs e.g., BiPV applications. To tackle this challenge stress profile specific PV module construction will be needed. Those stress profiles must contain the main stressors such as temperatures (ambient and component), temperature changes, number of freezing cycles, wind direction, wind speed, irradiance profiles including amounts of UV-light. Additionally, more seldom loads such as snow loads, high winds or hailstorms must be considered for mechanical stability and possible electrical safety hazards. As more installations are built in sandy and dusty climates this is an extra stress factor to address. Soiling, among other things, not only can cause a reduction in performance [2,3], but it can also add extra stressors by e.g., cleaning robots.

In the past, several classifications were proposed to assess the impact of the climate. Most often the Köppen-Geiger scheme [4,5] is used, developed in the 1930 s and updated over the years (e.g., [6–9]). Alternatives are the USDA hardiness zones [10] and similarly, such zones were developed basically for all regions. However, the focus for classification is on plant growth, not on photovoltaic application. More recently the Köppen-Geiger scheme was updated also to include more the relevant information for PV-systems [11]. To better assess the climate induced stress factors such as high temperatures, temperature fluctuations, humid heat, wind stress, and UV exposure the current work goes into PV specific climate zone classifications. Those should provide more quantitative thresholds for climate specific stressors [12]. With the use of several assumptions of specific degradation [13–16] and known acceleration modes [17,18], Ascencio-Vasquez et al. [19] determined global maps of degradation rates. Those maps give a great overview and are a fast way to have a first indication on possible stressors. However, they are not very specific and do not include local phenomena or different types of installations.

For reliable and durable modules several aspects (materials, design, processes, and location of use) must be considered. The degree of detail defines the need for a particular good data set. Influence of materials, product design and production process are out of scope of the paper, but for instance material selection should be such, that the material can withstand the expected stressors such as temperature and humidity impact.

The first thing that is always done while planning a PV system is to perform an energy yield assessment. Software is used to predict the energy production potential. This is typically done using TMY-datasets (hourly data) [20]. Those forecasts are nowadays quite good and serve as base for financing projects. The second thing to consider is the assumed longevity of the PV modules, but also all other components. Today, most modules are sold worldwide without differencing the significant different climatic conditions. This paper and the definition of Mission Profiles (MPs) is aimed to simplify the climate assessment of a particular location and support EPCs, installers, but also manufactures to better understand possible technical risks. MPs will help to better understand the climatic needs in a particular region compared to other known regions and failure modes for PV module and other BOS components. This should allow to better predict particular failure rates (see varying degradation rates e.g., collected by Jordan and others [21–24]) and in future to better build Mission Profile / climate specific modules that can have service lives longer than those of today.

2 Mission profile

2.1 Definition

The concept of Mission Profiles (MP) is aimed to make an assessment for PV module durability more location and installation specific. Other industries use this concept as well to better understand the needs to fulfill product needs/expectations and to avoid costly warranty claims or recall campaigns.

A Mission Profile is a simplified representation of all relevant static and dynamic load profiles that a population of electrical, mechanical, electronic, and electro-mechanical components is exposed during their entire life cycle (expected service life) [25]. The term “Load” describes environmental loads or a functional load that applies to a component within an operating mode. Generally, loads for a PV module are mainly mechanical, thermal, electrical, chemical type and fundamentally most relevant radiation. The latter interacts with all other load types in one or the other way such as extra heat, high voltages or as an extra driving force for electro-chemical reactions.

2.2 Concept use

As climatic maps such as from Köppen-Geiger are a great and fast way to get a first understanding, they lack the level of detail. On the other hand, over-engineered protocols may be fundamentally correct but not of practical use. MPs are aimed to bridge the gap and offer a fast method to focus on main differences between old and new installation locations and further utilize historic knowledge of failures to better assess the needs of a new location.

The knowledge for understanding of PV module reliability and failures is based mainly on the PV installations in temperate climates such as middle Europe. Long term historic weather and PV performance data is available for temperate climates such as Germany. These temperate climate conditions serve as reference and are basically the base line for known failures such as ribbon fatigue [26], cell crack growth [27], discoloration, embrittlement, degradation of polymers [28–31], general degradation rates [21–23], and forecasted rates [19].

This understanding is also the fundament for most PV standards (e.g., type approval IEC 61215-series [32]). However, today's most strongly growing PV installation markets are such as the Middle East or desert areas in the USA. There the climatic conditions are very different as such places are known to be very sunny and warm. To better address the stressors in those areas more focus must be on temperature, daily temperature cycle, impact of partly very low humidity and high irradiance (particularly UV) levels combined with high ambient and module temperatures. Standardization work to address the need for extensive thermal cycling [33], temperature and UV is ongoing [34]. Especially the updates on IEC 63126 [34] will be important to monitor and are important not only for the selection of PV modules but also for other BOS as reference to IEC 63126 will be added to the installation standards (e.g., IEC 60364-7-712 [35]).

Within this contribution, the focus lies on a comparison of MPs for a) UV + temperature, b) temperature and relative humidity and c) daily temperature cycling loads. High resolution data sets for a temperate climate like Germany and a desert-like climate as in the Middle East region is used. The aim is to focus on the most relevant difference in each single- and double stress MP. This is done on the one hand side by just visually comparing the MP histograms and on the other hand a more quantitative stress comparison is done by using acceleration assumptions by different Arrhenius-approaches (temperature acceleration). A three factor MP with a combination of UV, temperature (ambient and module) and relative humidity will not be considered herein. The local microclimate [17] has further dependencies and is out of scope within this paper.

With the understanding of main differences, it is possible to link known failures to other climatic conditions. This will help to better understand field observations and support the risks assessment (technical and finally financial) of new installations for new locations and new types of installations. Furthermore, it will guide the development of new testing protocols to adapt (define the right magnitude of stressors, more appropriately select the test duration and the combination of such) them to the new locations and types of installation. This understanding can be used to enhance e.g., the extended and sequenced stress tests IEC technical specification [36–39].

3 Methodology

In the past decades knowledge was gained from indoor testing and the hands-on experience from a lot of PV systems installed globally with various types of PV module technologies, designs, quality of workman ship, operation, and maintenance (O&M) procedures. However, most of such systems were installed in temperate and Mediterranean climates (e.g., England, Spain, Italy, Germany), not in hot desert areas.

To link the understanding of past, but also better design tests for new modules and locations, a detailed comparison of climate data is very helpful. Mission Profiles can support this as they first do not rely on PV specific data, but that can be added and make the methodology not only applicable to components in the “shade” but also for PV modules.

The comparison will be given by a dataset from a temperate climate (Germany, site near Halle (Saale)) and a hot climate (UAE, site near Dubai). The assessment is done on weather station data and excludes in the beginning any orientation of the modules. For calculating module temperatures, the mounting situation must be considered. Tilt angle, in plane irradiance, wind, wind direction and mounting structure, as well as ventilation play a significant role to accurately determine PV module temperatures in various mounting configurations. For simplicity, herein a simplified approach is used as described in [40–43].

Note: The frequencies given in all plots are arbitrary units. This is due to different time resolution of the data, but also due to some filters. E.g., temperature and humidity account for 24h a day, UV intensity only for daytime and a filter was set to only include irradiance data above 40 W/m2 of full spectrum intensity to remove data with high noise ratio and high faulty probability.

3.1 Single-stressor mission profiles

The simplest approach to summarize environmental stress loads is to look at e.g., annual load histograms. Depending on the component to look at, this could be already sufficient to screen for significant stress load differences between different locations.

3.1.1 MP: UV

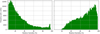

It is known that in desert regions the intensity, especially UV, is significantly higher. This is clearly visible in the single-stressor MP for UV in Figure 1. UV within this contribution is the sum of UV-A and UV-B and was approximated from the full spectrum intensities and set to 9% total irradiance. The cumulative intensity for a full year (colored area in the graph) of the hot site is approximately 2.5 times higher compared to the temperate climate and agrees well with the expectation of the two locations (latitude and overall climatic conditions).

|

Fig. 1 Single-stressor MP for UV intensity for a hot (left) and a temperate (right) climate. |

3.1.2 MP: Temperature

Like the UV content, the ambient temperature in the hot and desert like climate is significantly higher. For the studied case this is around 20 K in average and is given in Figure 2. For a more detailed look that could be split into day and night, but for purely temperature driven reactions that is not necessary. Still, the tail on the left side (lower temperatures) for both sites represent night data, whereas the far right always is daytime data.

Temperature data can further be used to determine day-to-night and intraday temperature changes. Those are mainly responsible for fatigue mechanisms such as ribbon breakage. High temperature differences ΔT cause more damage compared to smaller changes. However, the number of temperature hubs finally also is important [44]. A day-to-night minimum and maximum MP for PV module temperature variations is exemplarily given in Figure 3. By adding intraday events the profile for the hot and desert-like location does not really change. However, for the temperate climate more events occur in the range below 20 K temperature change.

|

Fig. 2 Single-stressor MP for ambient temperature for a hot (left) and a temperate (right) climate. |

|

Fig. 3 Mission profile of module temperature hubs of a PV modules installed in a hot (green) Middle East and (orange) in a temperate climate like Germany. While the German system has a widespread in events from basically 0 K to ∼50 K, the Middle East side has most daily temperature cycles in the range from 30 K to 50 K. |

3.1.3 MP: Relative humidity rH

For a lot of chemical reactions moisture is essential to trigger the reactions. Often in combination with UV-light. However, moisture that is present also influence requirements for electric safety (clearance and creepage distances) and is therefore also important for all components used in PV applications. The histograms for the two sites are given in Figure 4. As expected, there is a lot of time with a very high relative humidity in the temperate climate and basically no occurrence of very low humidity levels. The opposite is true for the hot climate. But it must be noted that there is still a lot of times where the ambient humidity is above 50–60% and that the ambient temperature was during that time higher. This information is missing in such single-stressor plots and will be addressed in the next section.

As noted for the single-stress MP for temperature, the humidity profiles could be split in day- and nighttime. But for the discussion herein not relevant. Generally, higher humidity typically occurs in the nighttime, early morning, or late evening hours. Those combinations can lead directly to condensation on surfaces if the dew point is reached. For clear desert nights this is actually very likely to happen especially on dark colored surfaces like PV modules. If condensation occurs a full wet layer on surfaces exist and a basically unlimited reservoir for moisture increase and therefor reactions on the surface is present.

|

Fig. 4 Single-stressor MP for relative humidity for a hot (left) and a temperate (right) climate. |

3.2 Double-stressor mission profiles

The deficit of the single-stressor MPs is that any correlation is getting lost. This must be considered while using such profiles. For PV for most reactions more than one stressor is important. Therefore, this section should illustrate how important the look at combinations is, especially for PV modules where UV, temperature and humidity are important stressors. To understand detailed ongoing local surface and interface processes the concept of microclimate must be considered [45]. The presented MPs (single and double stressors) are derived from ambient conditions. This is a first approximation to determine potential main stress factors. For parts that are not directly exposed to the sun this a very good assumption. However, for the PV module itself it is more complex as the surface and internal parts are heated up by the sun and are during daytime warmer as ambient. A detailed microclimate must be determined [45]. If the ambient humidity levels should be used to have a better understanding of process of inner layers in the PV module a detailed diffusion study must be conducted, see for example [46].

As described above, this detailed consideration of microclimate is out of the scope of this paper.

3.2.1 MP: UV + Temperature

For any kind of polymer degradation, UV is a very relevant stressor. Typically, temperature does accelerate such reactions. However, moisture is also often necessary and must be considered. Therefore, the next section is given to consider impact of moisture and temperature. More precisely a set of data of UV, temperature and humidity must be used, but that's difficult to illustrate and to visually compare and therefor is out of scope of this introductory of MPs.

The MPs are given in Figure 5. A clear difference between the two sites is visible. The hot and very sunny climate not only has overall higher ambient temperatures but also a significant higher total annual sum of in-plane irradiance values (∼950 kWh/m2 vs 2.250 kWh/m2 per year). This data will be used in Section 3.4 to compare the irradiance / UV stress of both sites using an Arrhenius temperature acceleration approach with reasonable activation energies and a proportional impact of UV-intensity [18].

|

Fig. 5 MP for UV and ambient temperature for a hot (left) and a temperate (right) climate. The color code represents the frequency of the occurrence of temperature-UV-pairs. The images only include day-time data where total irradiance levels are above 40 W/m2. |

3.2.2 MP: Temperature + relative humidity rH

The correlation between temperature and relative humidity is therefore important as it drives faster moisture into the component or out, depending on water concentrations on both “sides”. Taking the data from a weather station is typically very reliable. That data represents the ambient conditions, not the detailed information of the device under stress. There is a general problem and will be discussed in the next section in more detail.

The MPs for the two sites are shown in Figure 6 and show sort of inverted intensities. Generally, higher ambient temperatures show lower relative humidity. Highest intensity, however, is for the hot site at high temperatures and low humidity, whereas highest intensity for the temperate site is more at lower temperatures but at higher humidity levels. It must be noted that by looking at the details there are also quite high relative humidity levels for the hot site (>40% rH), but at higher temperatures compared to the temperate climate (see orange markings).

The type of degradation and the activation energy will play a significant role in understanding the acceleration factor.

|

Fig. 6 MP for relative humidity and ambient temperature frequencies for a hot (left) and a temperate (right) climate. Images show full 24 h-datasets. The color code represents the frequency of the occurrence of temperature-rH-pairs. |

3.3 MP: dT ambient vs dT module

For most components in a PV system ambient temperature is most likely to be sufficient to define most relevant stressors. For the PV module and other fully to the sun exposed components the real component temperature is more relevant.

For PV modules some empiric equations are available to calculate the module temperature based on ambient temperature, wind speed (wind direction is typically missing) and most importantly irradiance (see e.g., [40,41] and for standard IEC references [42,43] and references therein). However, mostly such temperatures are a good approximation, but with changing module technology, type of installation (mono vs bifacial) new correction factors must be applied. The best case is to have real measured PV module or component temperatures. Unfortunately, those are seldomly available for new sites.

With the calculated module temperature, it is possible to check for temperature accelerated effects that are independent on moisture. If the module heats up due to the sun, the local relative humidity will change (typically decrease). Therefore, such moisture, temperature and UV-triggered processes are most difficult to assess and will not be further addressed herein. Generally, the detailed local environments are very complex. Absorption and desorption process co-exist and those are not only dependent on environmental boundary conditions, but also are strongly impacted by the used materials such as type of material, type of surface morphology and wetting properties.

Considering a degradation reaction of UV alone and accelerated by temperature the MPs from Figure 5 can be transformed in plots of module temperature and UV intensity. Equation (21) from [40] was used to transform ambient to module temperatures. The result for the two sites is given in Figure 7.

|

Fig. 7 MP for UV and calculated module temperature frequencies for a hot (left) and a temperate (right) climate. The images only include day-time data where total irradiance levels are above 40 W/m2. The color code represents the frequency of the occurrence of module temperature-UV-pairs. Note: the maximum temperature on x-axis is set to 75 °C, not to 55 °C as used in Figure 5. |

3.4 Stress factor estimation to compare locations

Based on the Mission Profiles it is possible to summarize the impact of a certain stressor. Detailed chemical reactions and interactions can be generally assessed. However, a more detailed model of the product of interest is needed and detailed simulations for e.g., diffusion processes must be done. Additionally, a fundamental material understanding is needed to correctly predict possible chemical or electro-chemical reactions.

The comparison of the different climates is done by using a simple and a modified Arrhenius acceleration approach. The simple approach only takes the activation energy and the temperature into account. The modified one, introduced by Peck [13] modified by Kaaya [18], is a combination of standard temperature acceleration process with an added impact factor for relative humidity. To cumulate the stress the formula reads

where Rstress is the total stress, C a rate constant, rH the relative humidity, n is an empiric correction factor (typical range from 1.5 to 2.0 [18]), EA is the activation energy (typical 0.4 to 1.1 eV [45,47,48]), k the Boltzmann constant and T the temperature of the device. EA and n are dependent on the type of reaction, i and a are the sum indices from the histograms. Originally the relationship was derived for electrolytic corrosion of bare aluminum metallization. It is assumed, that this process and reaction dependence is also applicable for other surfaces such used in PV. With this assumption in mind, a set of reasonable parameters [13,18,45] will be used to show the impact and sensitivity of the parameters for the acceleration of the reaction in the RESULT section.

4 Results

Depending on the goal of the comparison and the expected failure mode different results in terms of dominant degradation mode can be expected. This will be illustrated by the following two examples: a purely temperature and a temperature and humidity driven process.

4.1 Single stressor MP comparison for temperature driven process

If the reaction is mainly temperature driven the results for acceleration as function of assumed activation energy are given in Table 1 using standard Arrhenius-acceleration. The acceleration factor is the ratio between hot and temperate climate. The calculations were done using ambient temperature data (ambient T) and calculated module temperatures (module T). Moving from ambient to module temperatures a shift to higher rates is determined and expected as overall irradiance levels are significantly higher resulting in higher module temperatures and therefor higher acceleration factors.

Furthermore, the given acceleration factors show the expected dependence on activation energy. A hot climate results in more stress / degradation compared to the temperate climate. The factors are within “rule of thumb” expectations that each 7–10 K increase in temperature are adding a factor two to reaction rates. Based on determined average temperature difference of ∼20 K (see Fig. 2) and most often reported activation energies (0.7–0.9 eV) an acceleration factor for both climates between 6–10 seems most reasonable to conclude by comparing the sites. This factor is even higher if the assessment is done for PV modules.

Summary of temperature acceleration between a hot vs a temperate climate considering only ambient temperate and calculated module temperatures.

4.2 Double stressor MP comparison for temperature plus humidity driven process

Temperature only driven processes are important for thermal and thermo-mechanical failure modes. A data set for a MP for daily change of temperatures is given in Figure 3 and results for the use of such profiles is published e.g., in [44]. The focus in this section is on the combination of moisture and temperature.

For most polymeric degradation modes moisture is an essential part of the reaction equation. Taken relative humidity and temperature into consideration the results are more complex, as not only activation energy, but also the relative humidity factor must be considered, as not known for most processes. The modelling parameters were taken from Kaaya [18]. The results considering the hot and temperate climate data from Figure 6 and a set of activation energies (0.4 to 1.1 eV) combined with humidity factor n (1.7 to 2.1) is summarized in Figure 8. Each bar in the graph represents a comparison for a given EA and n for the two sites (hot vs temperate). The figure shows normalized stress (normalization point: EA = 0.7 eV, n = 1.9) for ease of comparison with reference to the hot climate. Interestingly the strong acceleration factor by temperature (see previous section) is significantly reduced for this kind of hydrolysis reaction. For moisture and temperature driven hydrolysis degradation both climates are very similar even with the wide used spread in activation energy and humidity factor n.

|

Fig. 8 Normalized stress comparison for the hot (normalization reference) and temperate climate. Based on that result both locations can be treated as almost equal for a moisture + temperature driven process like hydrolysis. Low EA show a higher stress for the hot climate versus higher EA reduce the relative stress. Note: This is a relative comparison, not an absolute. |

5 Summary

Mission Profiles (MPs) are a simplification to represent climatic stress factors. Depending on the question to answer different ambient stressors need to be considered and appropriately combined. With additional assumption (e.g., approximated module temperatures and impact of mounting structure, kind of stress acceleration) stress profiles can be easily determined and compared to known sites. This should help to better focus on the main needs for extended stress testing and appropriate product designs. This is not limited to PV modules and can be used in PV for all other PV system components.

The paper presented exemplarily a comparison of a hot and a temperate climate. If the degradation of a component is only temperature driven a simple Arrhenius approach can be used. This will result in an acceleration factor of 6–10 for the hot compared to the temperate climate, considering activation energies often found in the range between 0.7 and 0.9 eV. This considers components not directly heated by the sun as the reference is ambient temperature and not device temperature. If the PV module is under consideration a higher factor applies. The magnitude depends on the exact mounting situation and are given for a more open-rack mounted module.

Moisture and temperature driven processes are more difficult. The comparison for the two chosen data sets shows basically no difference for hydrolysis processes based on the ambient data. This result is good for e.g., cables and connectors in the shade. However, for PV module this is not applicable. As the sun heats up the PV module a very localized microclimate is created where both, temperature and local relative humidity are different compared to real ambient weather data. As shown in Table 1 using module temperature increases severity by temperature a lot. Therefore, it is expected that the rate will be accelerated by temperature but reduced by lower relative humidity levels close to the module. The later cannot be reliably calculated as temperature, relative humidity, wind speed, wind direction, etc. will impact the microclimate.

The bare cumulative UV-dose is approximately 2.5-times higher for the hot climate vs the temperate climate. The absolute stress induced by UV at elevated temperatures, however, will be significantly higher. This can be clearly seen in Figure 5 (ambient temperature) and even more pronounced in Figure 7 (calculated PV module temperature). Depending on the used activation energy (reasonable acceleration factor 6–10) the UV-dose impact and therefore ongoing degradation reactions can be 10–20 times higher in the hot climate. An additional factor to acceleration of chemical reactions by UV light and enhance the severity of hot climates is that there is more absolute UV content and more relative UV-B in the spectrum compared to the temperate climate but was assumed to be same inhere.

The results show that an increased UV dose is most relevant to test for hot and high irradiance climates compared to a temperate climate. The result also demonstrates that even for this hot climate hydrolysis reactions can be expected, and a certain damp-heat testing is still useful to perform.

In a next step a detailed study for temperature change is planned and data as exemplarily shown in Figure 3 will be used. This investigation should support the understanding for relevant thermal-cycling testing. First simulation results by simple daily minimum and maximum temperatures indicate a more than twice as high stress in the hot climate compared to the temperate climate (methodology in analogy to [44] and compared to IEC 62892 [33]). Within this study the current IEC 63126 [34] definitions as well as the upcoming modifications (to be published in 2024 [49]) will be reviewed.

Furthermore, a year-by-year comparison is planned. The aim for this is to investigate variability, but also to check for more severe weather conditions such as higher temperatures (drought) or storms/floods. Herein, high resolution data (30–60 s) was used. In a next step the applicability of 10, 15 or even 30 min data is planned as such data is more widely available on an annual basis. Within this work with more data sets, including also high-humidity and tropical regions, a comparison is planned between forecasted observations by Mission Profiles with real field observations (see e.g., for hot climate [50,51]).

This work was funded by the Federal Ministry for Economic Affairs and Climate Action in the project CTS1000+ with grant #03EE1028A and SegmentPV with grant #03EE1180B.

Author contribution statement

Bengt Jaeckel: Methodology design, data evaluation and writing of paper. Matthias Pander and David Daßler: result discussion and proof-reading. Jim Joseph John, Sagarika Kumar, Baloji Adothu: discussion, proof-reading and data sharing.

References

- ITRPV, International Technology Roadmap for Photovoltaic (ITRPV) − 2022 Results, April 2023 [Google Scholar]

- K. Ilseet al., Techno-economic assessment of soiling losses and mitigation strategies for solar power generation 3, 2303 (2019) [Google Scholar]

- IEA PVPS-Report T13-21, Soiling losses impact on the performance of photovoltaic power plants, 2022, and references therein [Google Scholar]

- W. Köppen, Klassifikation der Klimate nach Temperatur, Niederschlag und Jahreslauf, Petermanns Geographische Mitteilungen 64, 193 (1918) [Google Scholar]

- W. Köppen, R. Geiger, Das geographische System der Klimate in Handbuch der Klimatologie, (Gebrüder Bornträger, Berlin, 1936) [Google Scholar]

- M. Kottek et al., World map of the Köppen-Geiger climate classification − updated, Meteorologische Zeitschrift 15, 259 (2006) [CrossRef] [Google Scholar]

- F. Rubel, M. Kottek, Observed and projected climate shifts 1901-2100 depicted by world maps of the Köppen-Geiger climate classification, Meteorologische Zeitschrift 19, 135 (2010) [CrossRef] [Google Scholar]

- D. Cui, S. Liang, D. Wang, Observed and projected changes in global climate zones based on Köppen climate classification, WIREs Climate Change 12, e701 (2021) [CrossRef] [Google Scholar]

- http://koeppen-geiger.vu-wien.ac.at/ and references given therein [Google Scholar]

- P. Del Tredici, The new USDA plant hardiness zone map, (1990), https://api.semanticscholar.org/CorpusID:131750956 [Google Scholar]

- J. Ascencio-Vasquez, K. Brecl, M. Topič, Methodology of Koppen-Geiger-Photovoltaic climate classi-fication and implications to worldwide mapping of PV system performance, Sol. Energy 191, 672 (2019) [CrossRef] [Google Scholar]

- T. Karin, C. Birk Jones, A. Jain, Photovoltaic degradation climate zones in 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC) (IEEE, 2019) [Google Scholar]

- D.S. Peck, Comprehensive model for humidity testing correlation, in 24th International Reliability Physics Symposium, Anaheim, CA, USA, 1986, pp. 44–50 [Google Scholar]

- C. Schwingshackl et al., Wind effect on PV module temperature: analysis of different techniques for an accurate estimation, Energy Procedia 40, 77 (2013) [CrossRef] [Google Scholar]

- T. Huld, A.M. Gracia Amillo, Estimating PV module performance over large geographical regions: the role of irradiance, air temperature, wind speed and solar spectrum, Energies 8, 5159 (2015) [CrossRef] [Google Scholar]

- A. Buck, New equations for computing vapor pressure and enhancement factor, J. Appl. Meteorol. Climatol. 20, 1527 (1981) [CrossRef] [Google Scholar]

- M. Koehl, M. Heck, S. Wiesmeier, Modelling of conditions for accelerated life time testing of Humidity impact on PV-modules based on monitoring of climatic data, Sol. Energy Mater. Sol. Cells 99, 282 (2012) [CrossRef] [Google Scholar]

- I. Kaaya et al., Modeling outdoor service lifetime prediction of PV modules: effects of combined climatic stressors on PV module power degradation, IEEE J. Photovolt. 9, 1105 (2019) [CrossRef] [Google Scholar]

- J. Ascencio-Vasquez et al., Global climate data processing and mapping of degradation mechanisms and degradation rates of PV modules, Energies 12, 4749 (2019) [CrossRef] [Google Scholar]

- https://www.pvsyst.com/help/meteo_tmy_data_generation.htm [Google Scholar]

- D. Jordan, S.R. Kurtz, Photovoltaic degradation rates − an analytical review, Prog. Photovolt.: Res. Appl. 21, 12 (2013) [CrossRef] [Google Scholar]

- D. Jordan, S.R. Kurtz, K. VanSant, J. Newmiller, Compendium of photovoltaic degradation rates, Prog. Photovolt.: Res. Appl. 24, 978 (2016) [CrossRef] [Google Scholar]

- D. Jordan, B. Marion, C. Deline, T. Barnes, M. Bolinger, PV field reliability status − analysis of 100 000 solar systems, Prog. Photovolt.: Res. Appl. 28, 739 (2020) [CrossRef] [Google Scholar]

- M. Aghaei et al., Review of degradation and failure phenomena in photovoltaic modules, Renew. Sustain. Energy Rev. 159, 112160 (2022) [CrossRef] [Google Scholar]

- http://www.mpfo.org/mpfo-0.7/mpfo_ch_introduction.html (modified) [Google Scholar]

- St. Großer, in Untersuchung der Korrosionsstruktur am massiv korrodiertem Quer-verbinder, PV Symposium Bad Staffelstein, 2023 [Google Scholar]

- B. Jaeckel, Th. Franke, J. Arp, Long term statistics on micro cracks and their impact on performance, in 31st European Photovoltaic Solar Energy Conference, 2015 [Google Scholar]

- M.D. Kempe, J.H. Wohlgemuth, Evaluation of temperature and humidity on PV module component degradation, in 2013 IEEE 39th Photovoltaic Specialists Conference (PVSC) (2013), pp. 0120–0125 [CrossRef] [Google Scholar]

- R. Heidrich, Spatially resolved degradation analysis of solar modules after combined accelerated aging, in 50th IEEE Photovoltaic Specialists Conference PVSC, submitted, 2023 [Google Scholar]

- R. Heidrich, UV lamp spectral effects on the aging behavior of encapsulants for photovoltaic modules, submitted to Sol. Energy Mater. Sol. Cells(2023) [Google Scholar]

- R. Wieser et al., Field retrieved photovoltaic backsheet survey from diverse climate zones: analysis of degradation patterns and phenomena, Sol. Energy 259, 49 (2023) [Google Scholar]

- IEC 61215-series: terrestrial photovoltaic (PV) modules − design qualification and type approval [Google Scholar]

- IEC 62892: Extended thermal cycling of PV module [Google Scholar]

- IEC TS 63126: Guidelines for qualifying PV modules, components and materials for operation at high temperatures [Google Scholar]

- IEC 60364-7-712: Low voltage electrical installations − Part 7-712: Requirements for special installations or locations − Solar photovoltaic (PV) power supply systems [Google Scholar]

- IEC TS 63209-1: Photovoltaic modules − Extended-stress testing [Google Scholar]

- IEC TS 63209-2: Photovoltaic modules − Extended-stress testing − Part 2: Polymeric component materials [Google Scholar]

- IEC TR 63279: Derisking photovoltaic modules − Sequential and combined accelerated stress testing [Google Scholar]

- IEC 62788-series: Measurement procedures for materials used in photovoltaic module [Google Scholar]

- E. Skoplaki, A.G. Boudouvis, J.A. Palyvos, A simple correlation for the operating temperature of photovoltaic modules of arbitrary mounting, Sol. Energy Mater. Sol. Cells, 92, 1393 (2008) [CrossRef] [Google Scholar]

- E. Skoplaki, J.A. Palyvos, On the temperature dependence of photovoltaic module electrical performance: a review of efficiency/power correlations, Sol. Energy 83, 614 (2009) [CrossRef] [Google Scholar]

- IEC 61853-2: Photovoltaic (PV) module performance testing and energy rating − Part 2: Part 2: Spectral responsivity, incidence angle and module operating temperature measurements [Google Scholar]

- IEC 61853-3: Photovoltaic (PV) module performance testing and energy rating − Part 3: Energy rating of PV modules [Google Scholar]

- U. Zeller et al., Digitalization in PV–virtual application of real weather data on PV modules for lifetime prediction, in EUPVSEC, 2018 [Google Scholar]

- M. Koehl, Modeling of the nominal operating cell temperature based on outdoor weathering, Sol. Energy Mater. Sol. Cells 95, 1638 (2011) [CrossRef] [Google Scholar]

- Ph. Hülsmann, M. Heck, M. Köhl, Simulation of water vapor ingress into PV-modules under different climatic conditions, J. Mater. 2013.102691 (2013) [Google Scholar]

- M. Pander, Forecasting potential power/energy yield loss due to LeTID susceptible modules, in PV Symposium Bad Staffelstein, 2019 [Google Scholar]

- K. Naveršnik, R. Jurečič, Humidity-corrected Arrhenius equation: the reference condition approach, Int. J. Pharm. 500, 360 (2016) [CrossRef] [Google Scholar]

- IEC 63126 project webpage: https://www.iec.ch/dyn/www/f?p=103:38:-317145204867572::::FSP_ORG_ID,FSP_APEX_PAGE,FSP_PROJECT_ID: 1276,23,112692 [Google Scholar]

- B. Adothu, Identification and investigation of materials degradation in photovoltaic modules from middle east hot desert, in EUPVSEC, 2023 [Google Scholar]

- S. Kumar, Defects and degradations in PV modules from hot Middle East deserts, in EUPVSEC, 2023 [Google Scholar]

Cite this article as: Bengt Jaeckel, David Daßler, Matthias Pander, Jim Joseph John, Sagarika Kumar, Baloji Adothu, Mission profile concept for PV modules: use case – middle east deserts vs temperate European climate, EPJ Photovoltaics 14, 39 (2023)

All Tables

Summary of temperature acceleration between a hot vs a temperate climate considering only ambient temperate and calculated module temperatures.

All Figures

|

Fig. 1 Single-stressor MP for UV intensity for a hot (left) and a temperate (right) climate. |

| In the text | |

|

Fig. 2 Single-stressor MP for ambient temperature for a hot (left) and a temperate (right) climate. |

| In the text | |

|

Fig. 3 Mission profile of module temperature hubs of a PV modules installed in a hot (green) Middle East and (orange) in a temperate climate like Germany. While the German system has a widespread in events from basically 0 K to ∼50 K, the Middle East side has most daily temperature cycles in the range from 30 K to 50 K. |

| In the text | |

|

Fig. 4 Single-stressor MP for relative humidity for a hot (left) and a temperate (right) climate. |

| In the text | |

|

Fig. 5 MP for UV and ambient temperature for a hot (left) and a temperate (right) climate. The color code represents the frequency of the occurrence of temperature-UV-pairs. The images only include day-time data where total irradiance levels are above 40 W/m2. |

| In the text | |

|

Fig. 6 MP for relative humidity and ambient temperature frequencies for a hot (left) and a temperate (right) climate. Images show full 24 h-datasets. The color code represents the frequency of the occurrence of temperature-rH-pairs. |

| In the text | |

|

Fig. 7 MP for UV and calculated module temperature frequencies for a hot (left) and a temperate (right) climate. The images only include day-time data where total irradiance levels are above 40 W/m2. The color code represents the frequency of the occurrence of module temperature-UV-pairs. Note: the maximum temperature on x-axis is set to 75 °C, not to 55 °C as used in Figure 5. |

| In the text | |

|

Fig. 8 Normalized stress comparison for the hot (normalization reference) and temperate climate. Based on that result both locations can be treated as almost equal for a moisture + temperature driven process like hydrolysis. Low EA show a higher stress for the hot climate versus higher EA reduce the relative stress. Note: This is a relative comparison, not an absolute. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.